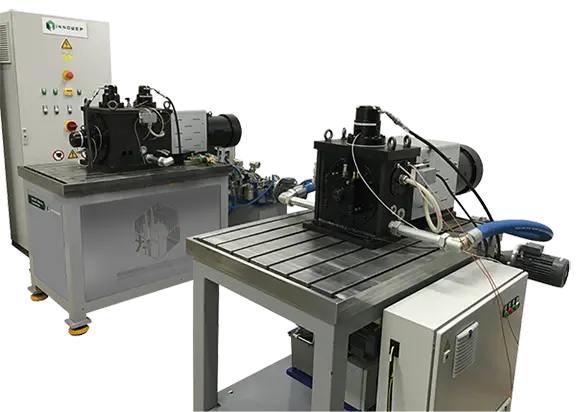

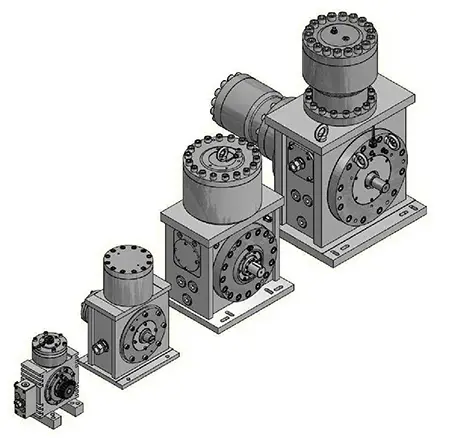

The FARAX®-Bearing-C is a fully modular test rig for fatigue and friction testing of diverse bearing types. With flexible configurations for load, lubrication, and speed, it enables the simulation of demanding real-world operating conditions. Thanks to its advanced measurement and control systems, it provides accurate evaluation of lubricant performance, bearing durability, and system behavior.

Designed for deep-groove, angular contact, thrust ball, spherical, cylindrical, tapered and needle roller bearings, the FARAX-C covers a wide spectrum of applications — from industrial R&D to e-mobility testing.

Applications

& Test Types

Features & Advantages

-

Modular test head adaptable to bearing type & size

(OD 30 – 500 mm) -

High-performance direct-drive motor

(7.5 – 19,800 rpm, flyer: 3,000 – 18,900 rpm) -

Pure axial, pure radial or combined axial/radial loading

-

Load capacity up to 100 kN (hydraulic)

-

Integrated lubrication unit (oil circulation, oil spray, drip)

-

Hydraulic or mechanical load application

-

Optional cooling & heating system

-

Flexible measurement:

-

Inline torque

-

Bearing temperature

-

Lubricant temperature

-

Vibration

-

Speed

-

Load

-

-

Electronic control cabinet with emergency shutdown

Technical Specifications

| Parameter | Value |

|---|---|

| Bearing size (OD) | 30 mm to 500 mm (Flyer: up to 450 mm) |

| Speed range | 7.5 – 19,800 rpm (Flyer: 3,000 – 18,900 rpm) |

| Loading system | Hydraulic or Mechanical |

| Load capacity | Up to 100 kN |

| Load modes | Pure axial / pure radial / combined |

| Lubrication options | Oil circulation, oil spray, oil drip |

| Measurement parameters | Torque, Temp. (bearing & lube), Vibration, Speed, Load |

| Control system | Electronic cabinet with data logging |

| Safety | Emergency shutdown, overload protection |

Typical Results

The FARAX®-Bearing-C test rig delivers in-depth insights into the fatigue behavior and friction characteristics of various bearing types. Typical outcomes include lifetime curves under defined load and speed profiles, trends in friction coefficient over time, and the impact of lubrication methods on bearing wear and performance. Detailed data on lubricant aging, vibration patterns, and heat generation is captured continuously, allowing precise analysis of endurance limits and failure modes. Combined with visual inspection of wear patterns and surface damage, the system provides a comprehensive view of bearing durability and lubricant efficiency across a wide range of operating scenarios.

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.