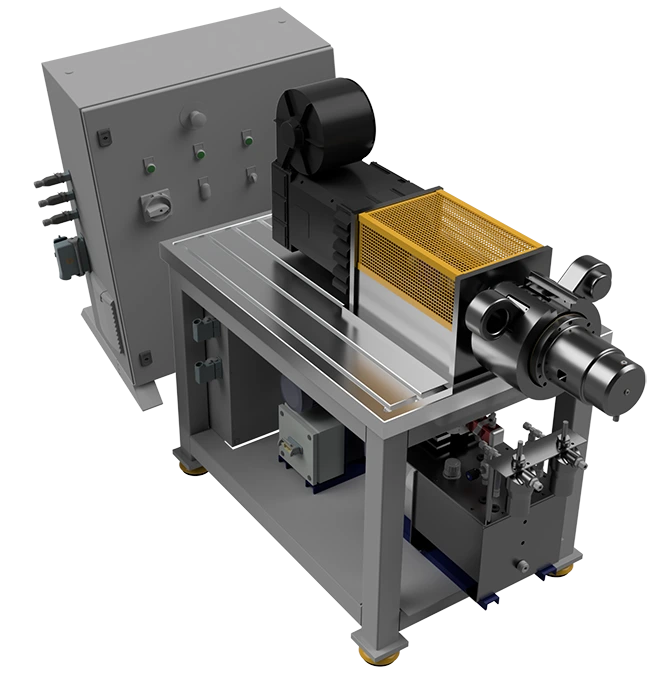

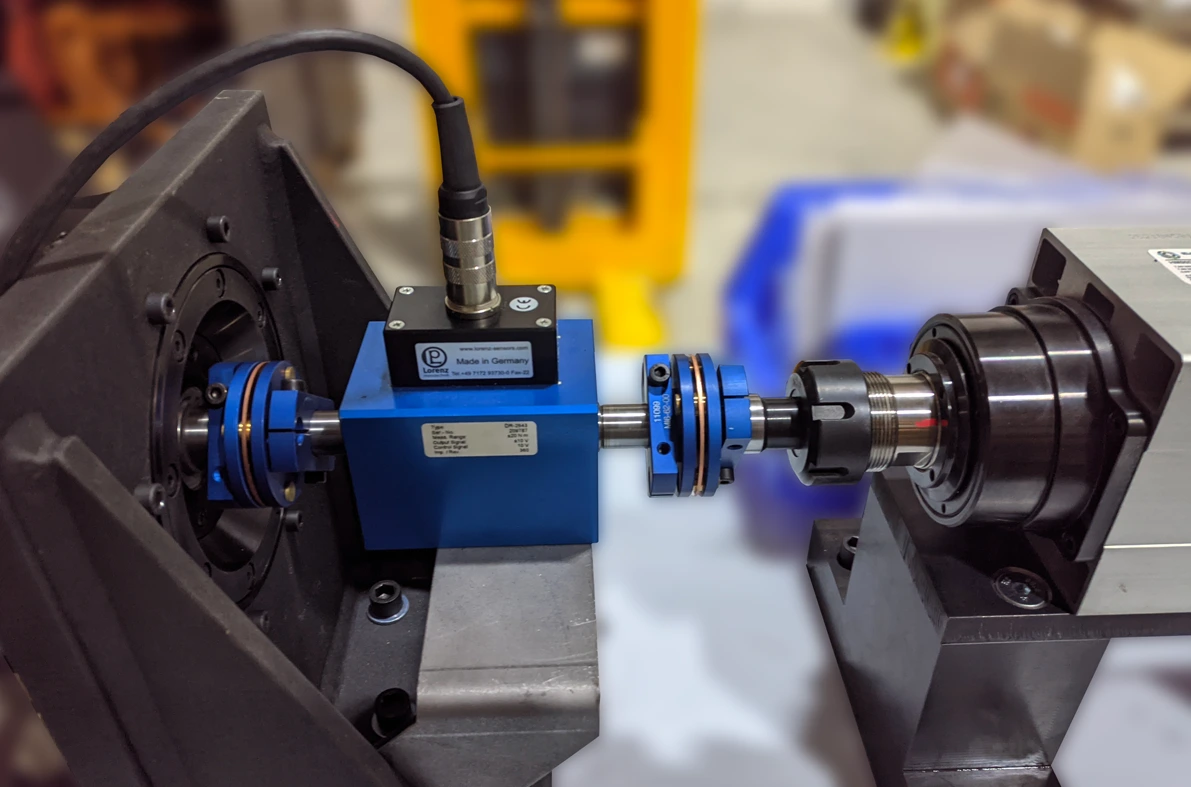

The FARAX®-Bearing-FE8 is a high-precision bearing test rig designed for evaluating lubricants and rolling bearings under defined tribological stress conditions. Developed in accordance with DIN 51819, the system enables the analysis of wear, friction, temperature behavior and endurance under axial load. FARAX-FE8 is available in two configurations:

- FE8-M with spring pack loading

- FE8-H with fully adjustable hydraulic loading

Both variants are suitable for single-station or multi-station setups.

Applications & Test Types

Features & Benefits

The FARAX®-FE8 platform allows precise and reproducible testing with the following highlights:

Test Methods:

Technical Specifications

| Parameter | Value |

|---|---|

| Standard | DIN 51819 |

| Test Speed Range | 7.5 – 4,500 rpm (adjustable) |

| Axial Load Capacity | 100 kN |

| Load System | Spring Pack (FE8-M) or Hydraulic (FE8-H) |

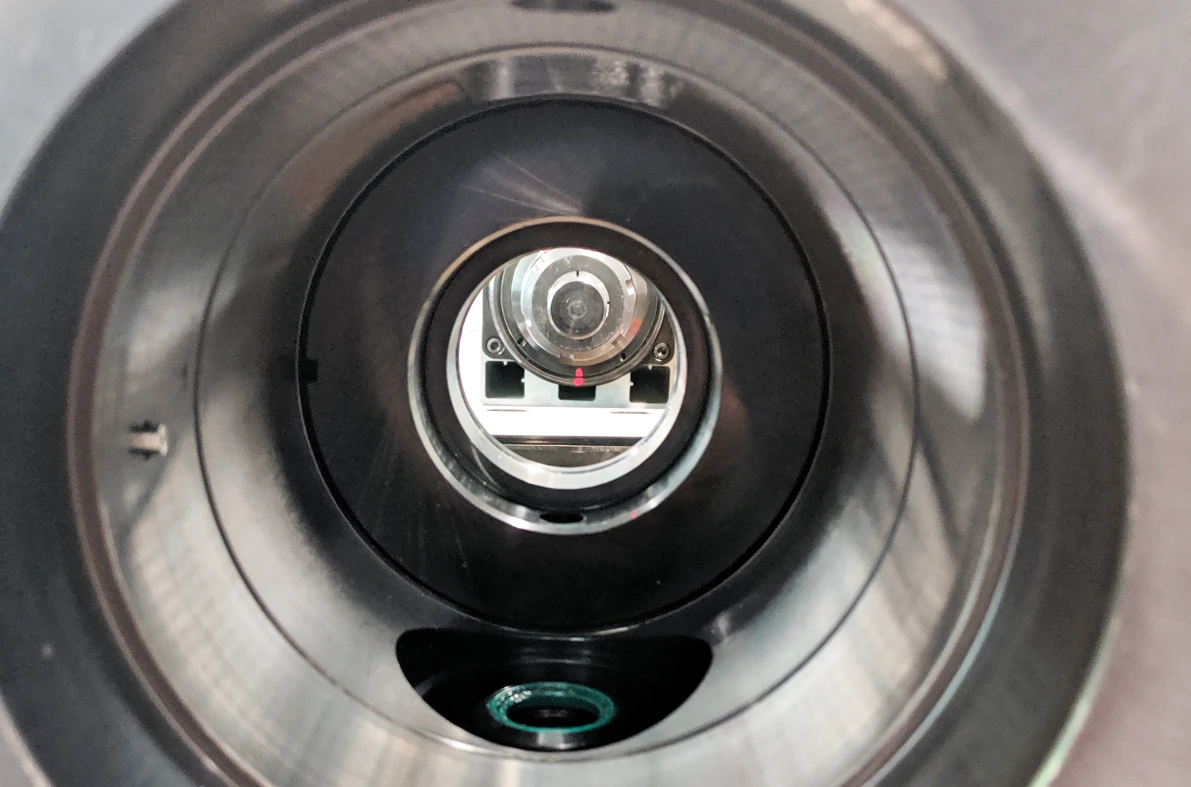

| Test Bearing | FAG 81212 / other standard types |

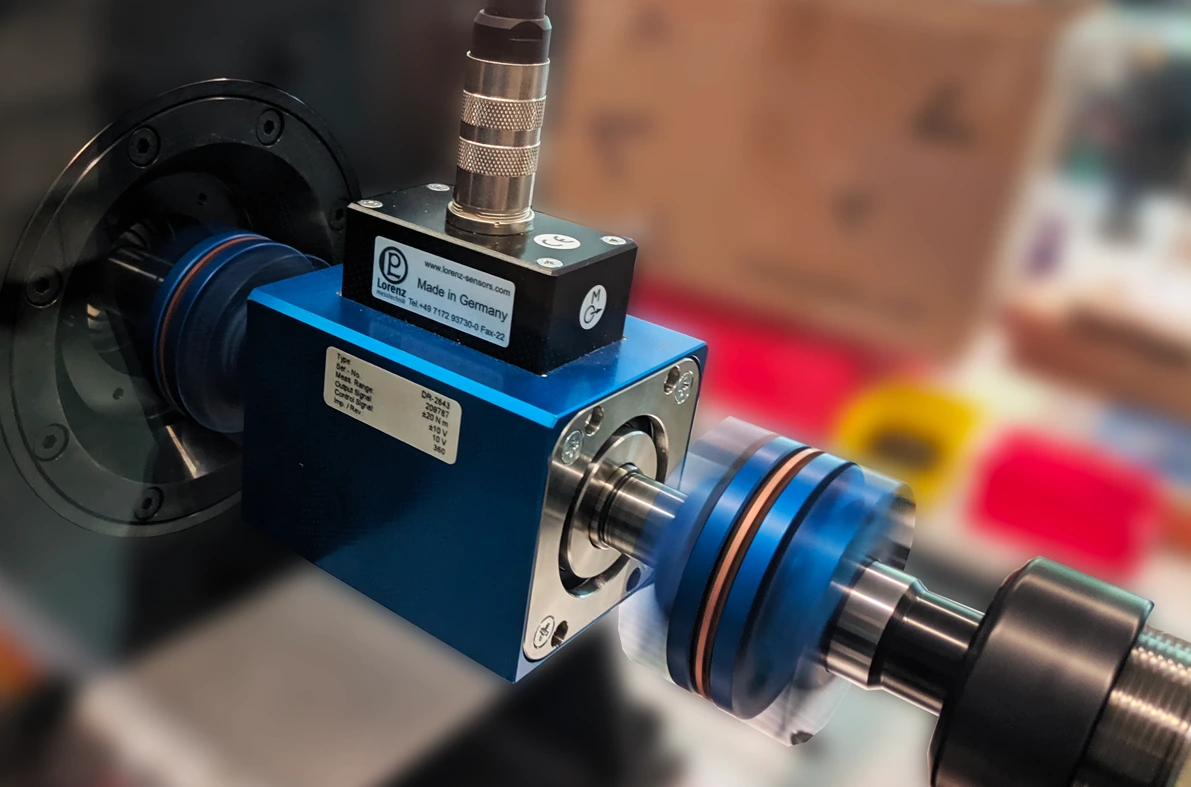

| Measurement Parameters | Torque, Speed, Temperature, µ |

| Operating Modes | Single-station / Multi-station |

Available Test Head Variants

-

Angular contact ball bearings (brass cage)

-

Taper roller bearings (metal cage)

-

Axial cylindrical roller bearings (brass cage)

Typical Results

-

Distinction of bearing conditions: “< 2 mg wear” vs. “> 100 mg wear”

-

Trend plots for torque, axial force, and friction over time

-

Graph-based evaluation and threshold-based wear failure detection

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.