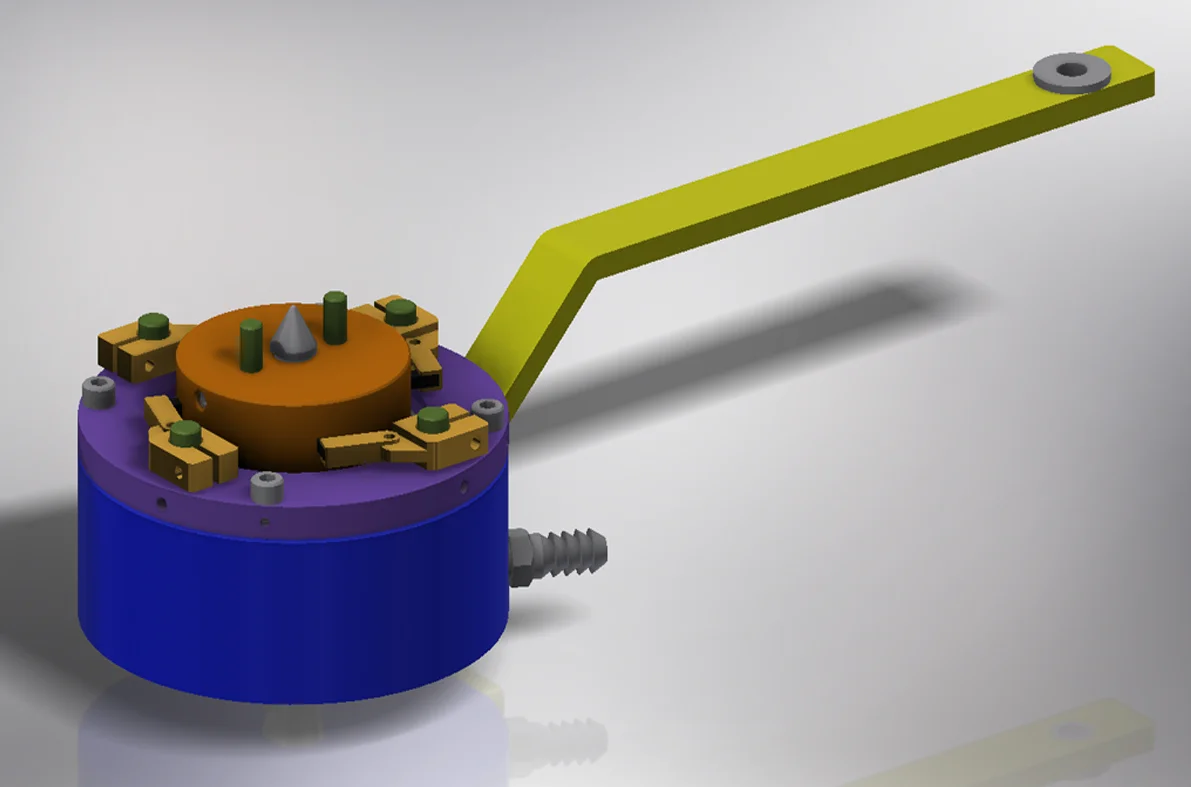

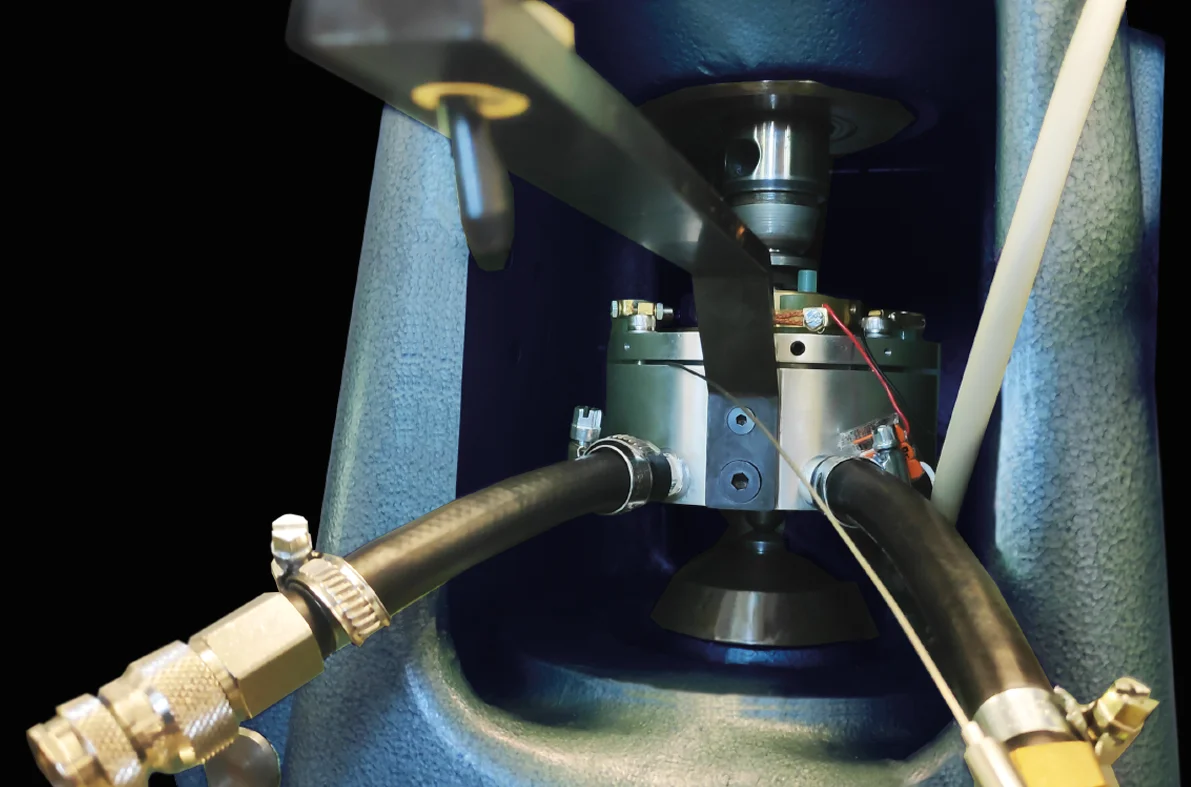

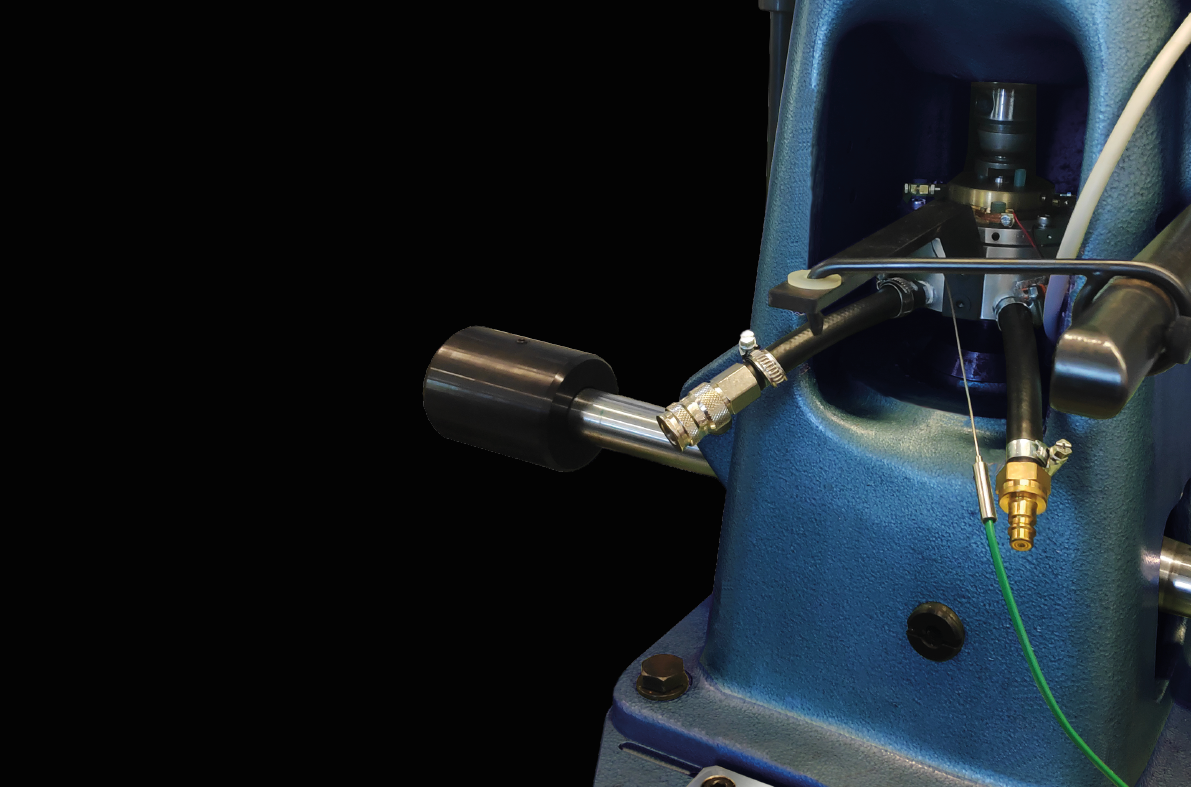

The FARAX®-VKA110 is a robust and proven test rig for evaluating the friction, wear, and extreme pressure behavior of lubricants. Based on the well-established Shell-Hansa VKA110 design, it plays a key role in lubricant development and quality control, particularly in routine testing environments.

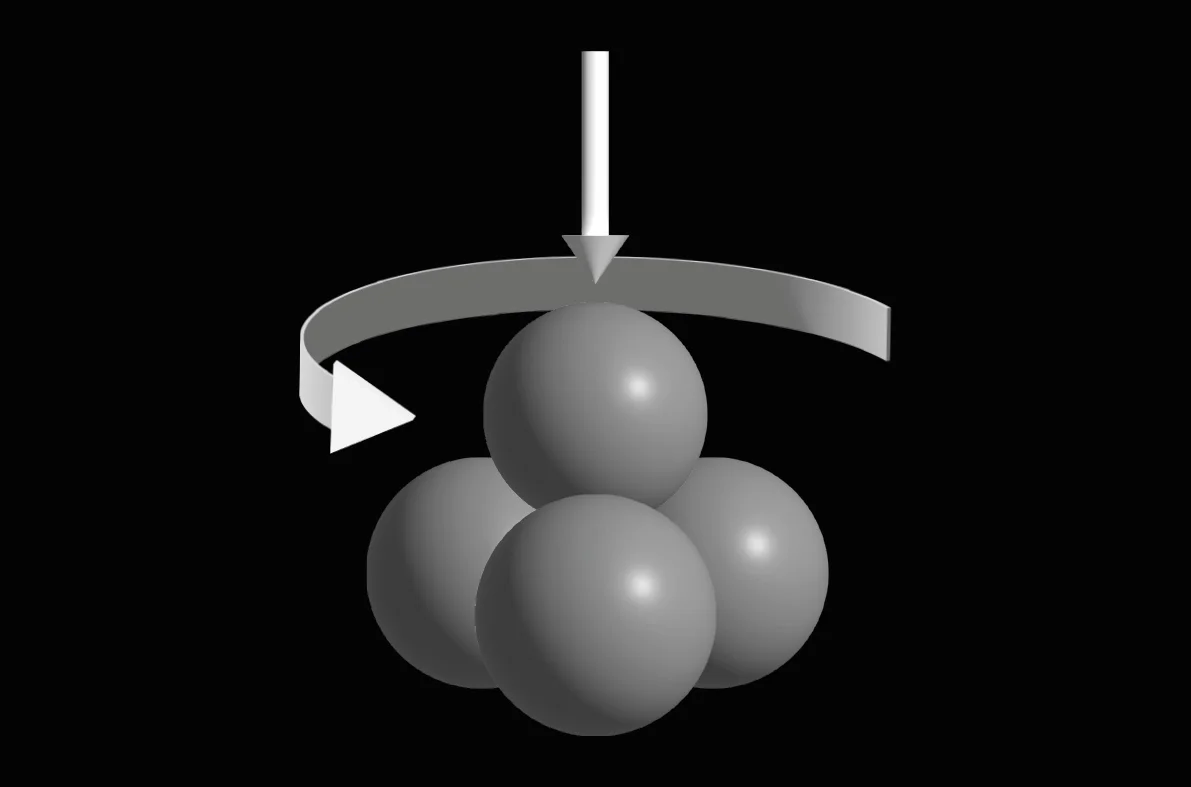

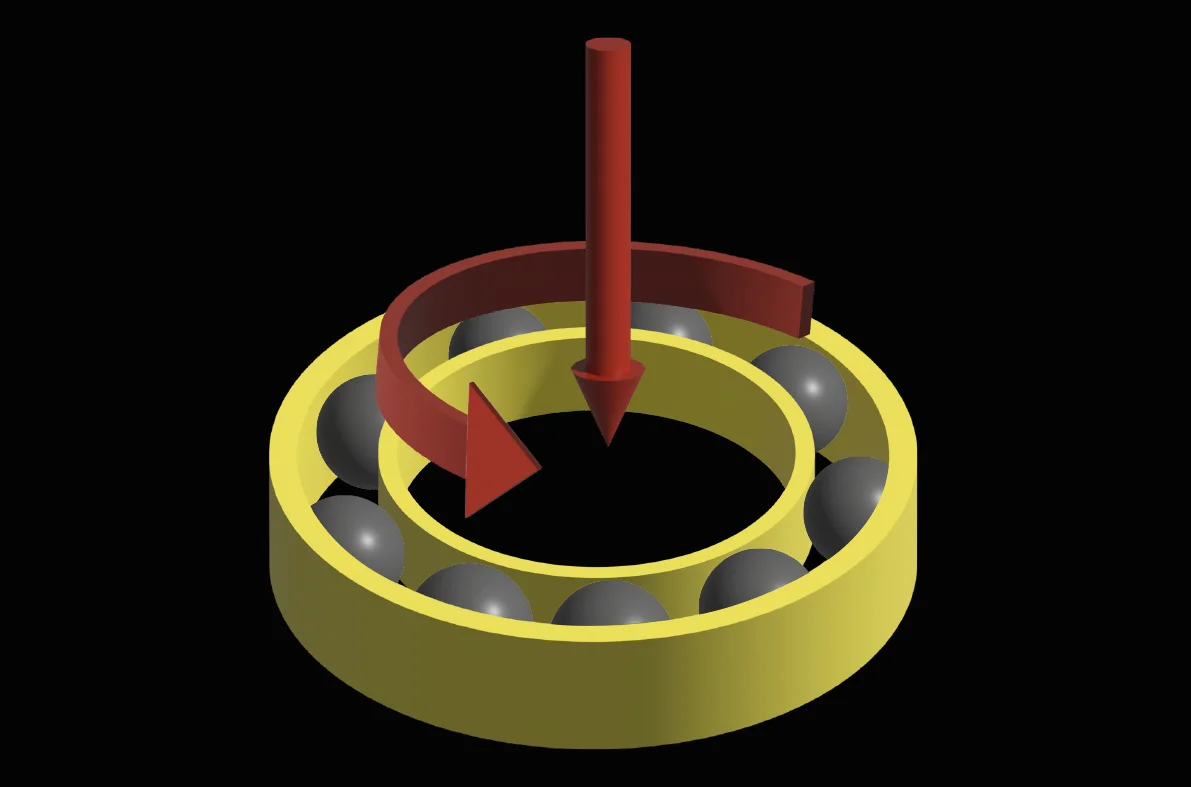

The classical four-ball test method applies a rotating ball against three stationary balls under load, continuously measuring friction torque, temperature, and load. Wear is determined through an integrated digital microscope and analysis software, allowing quick evaluation without the need to disassemble the test adapter.

Applications

FARAX®-VKA110 supports a wide range of international standards, including:

Beyond standard wear and friction tests, the rig also accommodates shear stability tests and other specialized analyses via interchangeable adapters.

System Features

The test rig covers:

-

Speeds from 10 to 5,800 rpm

-

Loads between 100 to 12,000 N

-

Temperature range from -30 °C to +150 °C

It supports sliding and rolling motion, while enabling precise measurement of mixed friction states, EHD (elastohydrodynamic) contact behavior, and key parameters like torque, temperature, transition resistance, and wear scar diameter.

Typical Use

Commonly used across the lubricants industry, FARAX®-VKA110 is trusted for routine product development and quality assurance of:

-

Lubricating greases

-

Oils

-

Additive formulations

Its flexible setup makes it equally valuable for R&D labs and industrial test departments.

Ready to optimize your lubricant performance? Contact us today to learn more about FARAX®-VKA110.

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.