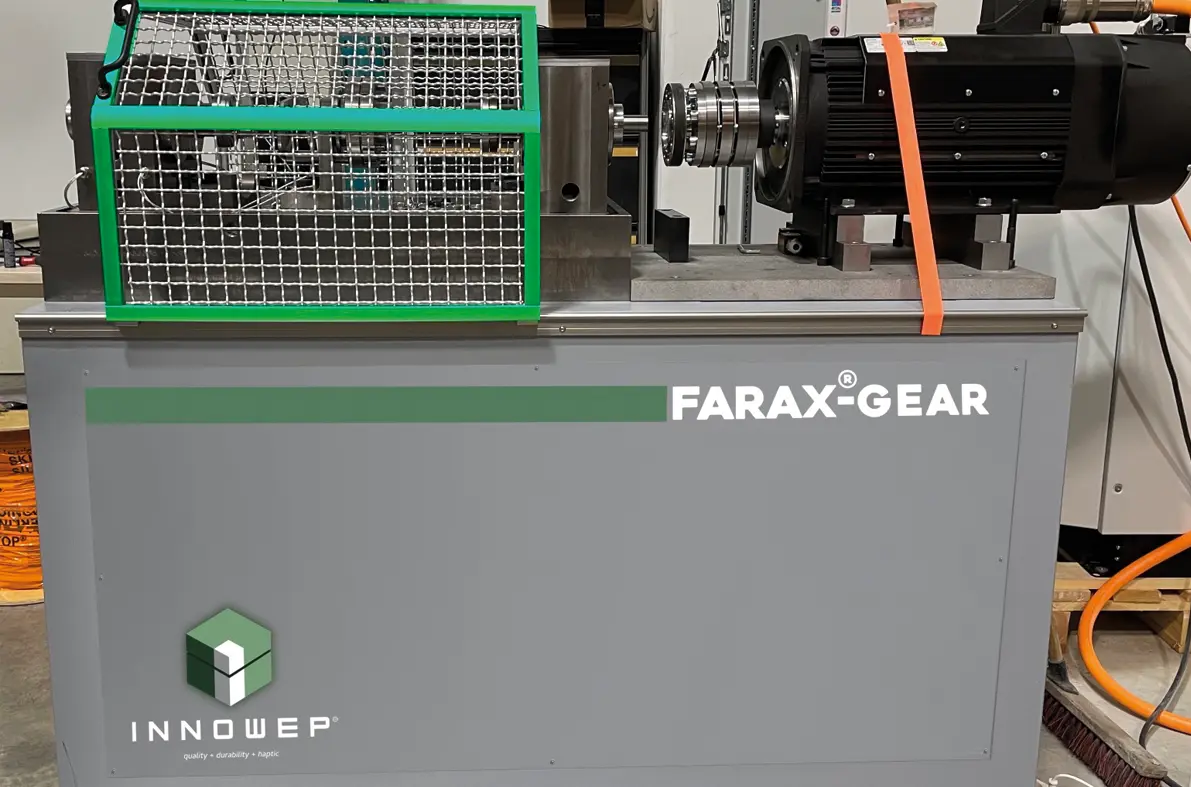

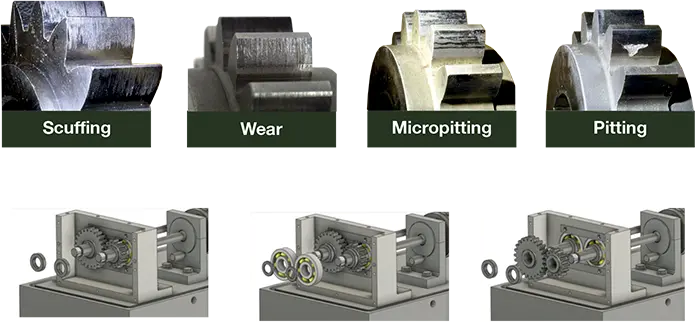

The FARAX®-Gear-H is a hydraulically loaded back-to-back gear testing machine, developed for advanced fatigue, wear, and lubricant testing under variable, high-torque conditions. With fully integrated torque sensors, temperature control, and a powerful hydraulic system (GAT MOOG), this model ensures stable, automated load application and precise, reproducible test results – even under dynamic cycling.

Applications and Test Types

FARAX®-Gear-H is ideal for:

Supported test standards:

ISO 14635, ASTM D5182, DIN 51354, CEC-L-07, FVA 243, FVA 345, and others.

Technical Specifications

| Parameter | Value |

|---|---|

| Speed range | 100 – 6,000 rpm (direct drive) |

| Torque | ±800 Nm (hydraulic load, GAT MOOG system) |

| Load system | Fully automatic hydraulic control |

| Center distance | 91.5 mm |

| Oil temperature | Up to 120 °C (immersion) / 90 °C (injection) |

| Drive | Electric motor, bi-directional rotation |

| Construction | Solid frame, 2 torque shafts, 2 gearboxes |

| Sensors | Integrated torque sensors |

| Software | LABVIEW-based control interface |

Request a callback or get in touch!

Request a callback or get in touch!

Our contact form makes the process simple, easy and fast.